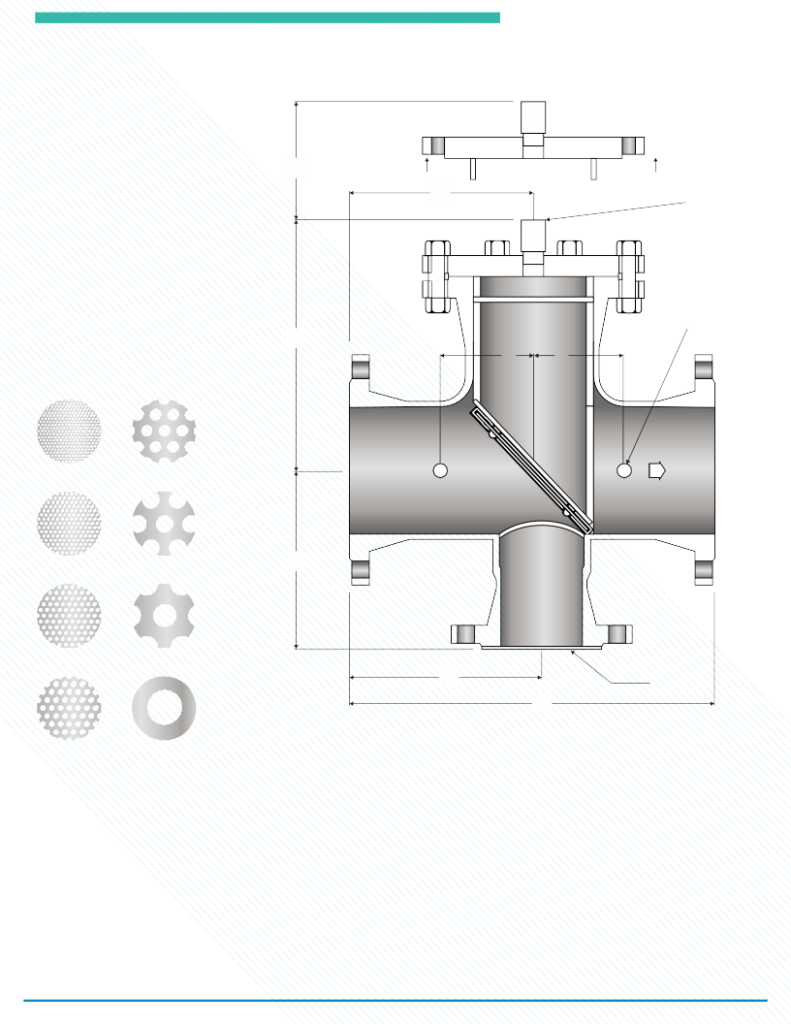

SELF CLEANING STRAINERS

Inline Flow Technologies’ strainer is a unique self-cleaning strainer. It utilizes a sump for collection of debris – not a basket. It can be cleaned without having to shut down operations – reducing downtime and maintenance costs. Since the strainer does not have to opened to remove a basket, it substantially reduces fugitive emission exposer to the environment and personnel to fugitive emissions.

Unlike Wye strainer, the Surgeaco strainer is suitable for small mesh size particulate and larger particulate removal.

Numerous options are available including spray nozzles and automated controls.

Materials of Construction

ASME Classes:

150/300/600/900/1500#

Body:

- Forged carbon steel std.

- Stainless steel

- Non-ferrous & non-metallic available

Seal:

- Buna, Viton

- Metal

- Specials available

Screen:

- Stainless steel perforated — sheet standard

- Stainless steel woven wire — mesh available

Improves operational efficiency.

Reduces fugitive emissions.

Eliminates Downtime

System does not need to be shut down to remove particulate

Reduces the Release of Potential Fugitive Emissions do not require removal of a cover

Improves Personnel Safety

lifting a cover and heavy basket is eliminated

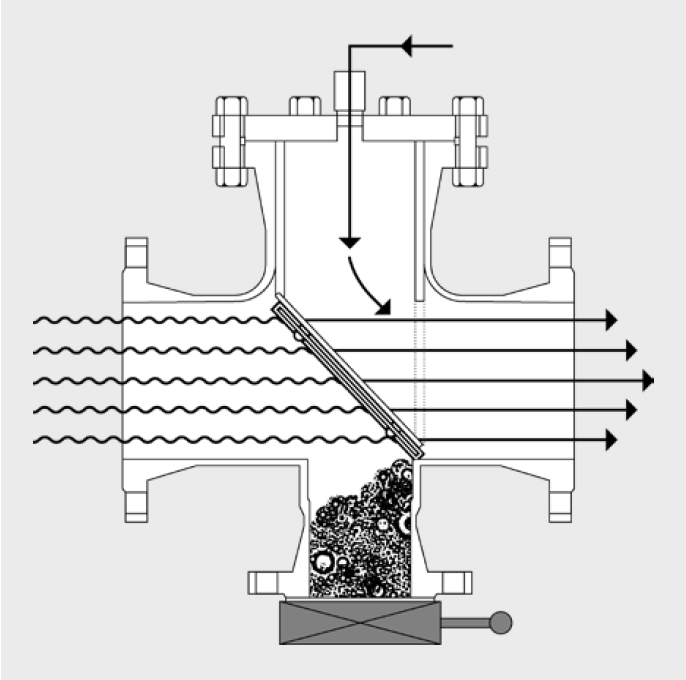

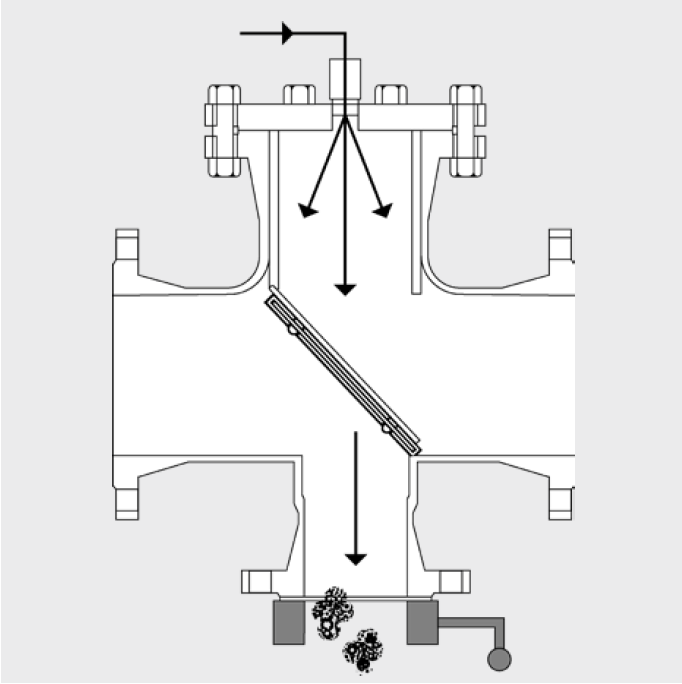

FLOW STRAINING

Particulate is trapped by the inclined low pressure drop screen, and through fluidized action, some of the material falls into the sump below.

With the drain valve in closed position, “recirc” fluid from the pressure head will join the downstream flow.

As debris accumulates across the screen face, the differential pressure will rise that can be sensed for manual or automatic cleaning.

DYNAMIC CLEANING

During operation, manual or automatic opening of the drain valve will cause a momentary pressure drop at the screen face by diversion of the principal flow through the sump. The pressure head fluid volume above the screen rear, being fed by the “recirc” pressure downstream, will initially backflush the screen until its energy dissipates.

Coupling this backflush with the simultaneous wiping action of the diversionary flow as it turns the corner at the screen front face will cause the accumulated debris to be flushed down and out of the sump.

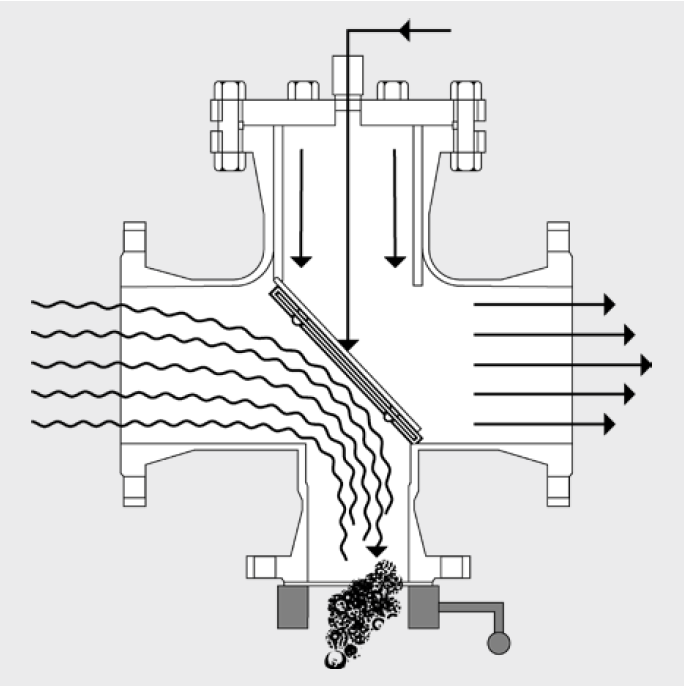

BACKWASH CLEANING

Soft or fibrous material may occasionally become impacted in the screen perforations and be difficult to remove during operation.

One or more spray nozzles can be placed on the pressure head chamber and can then be used with an auxiliary water supply to pressure backwash the screen. As this initial pressure is contained in the cylindrical housing over the screen, the line should be stopped and the drain valve opened during this operation.

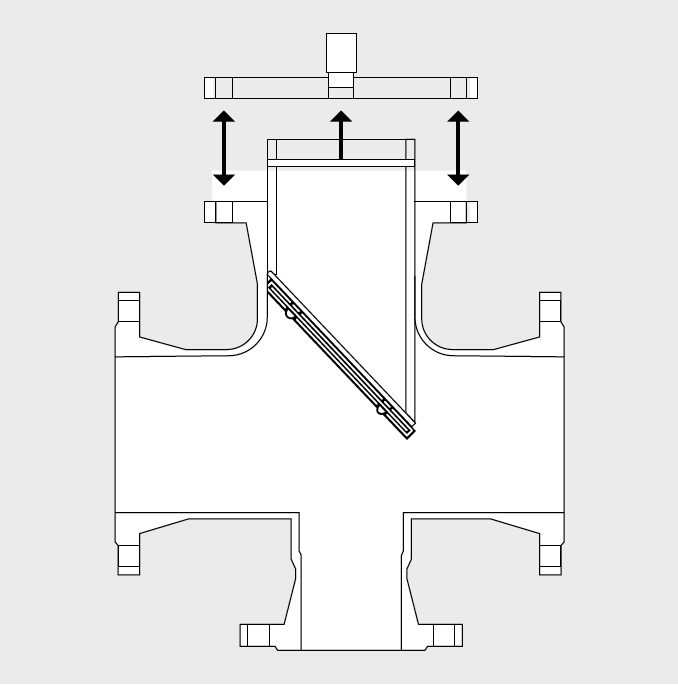

SCREEN REMOVAL

The screen may be easily removed from the strainer body without disturbing or dewatering the line.

Simply taking off the lid flange and pulling out the screen mount will reveal the screen fastened to the slanted face.

SURGE ARRESTORS

The surge arrestor is a unique design that has a non-pressurized engineered urethane liner to mitigate harmful water hammer pressure transients that can damage related piping and equipment.